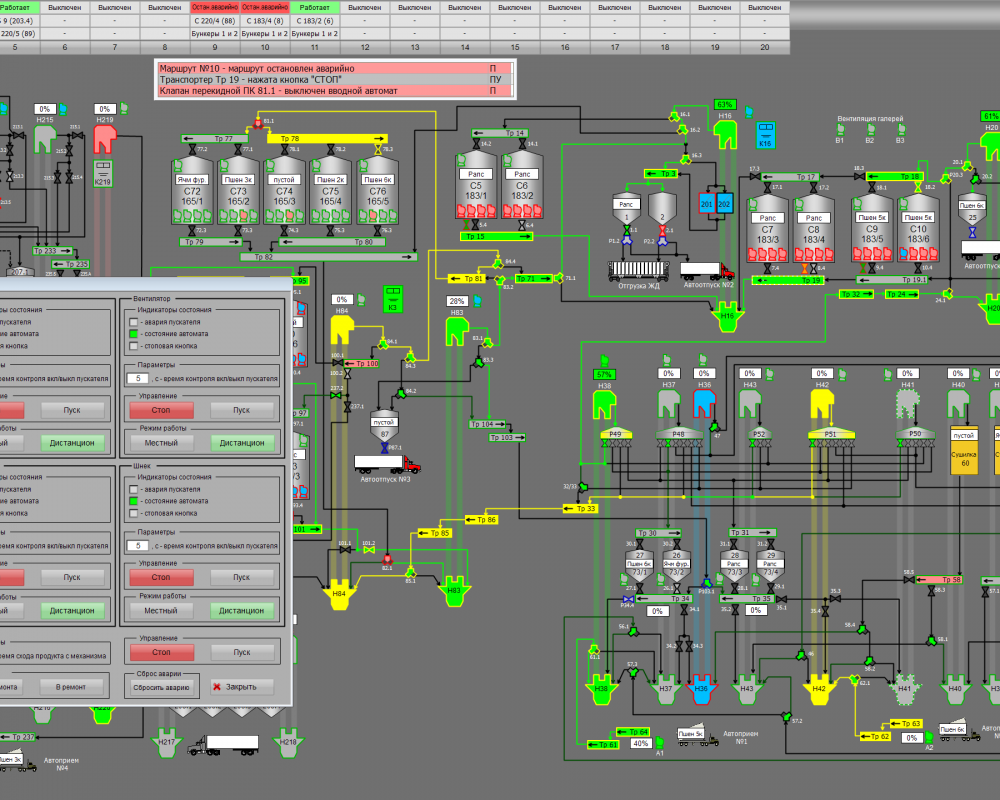

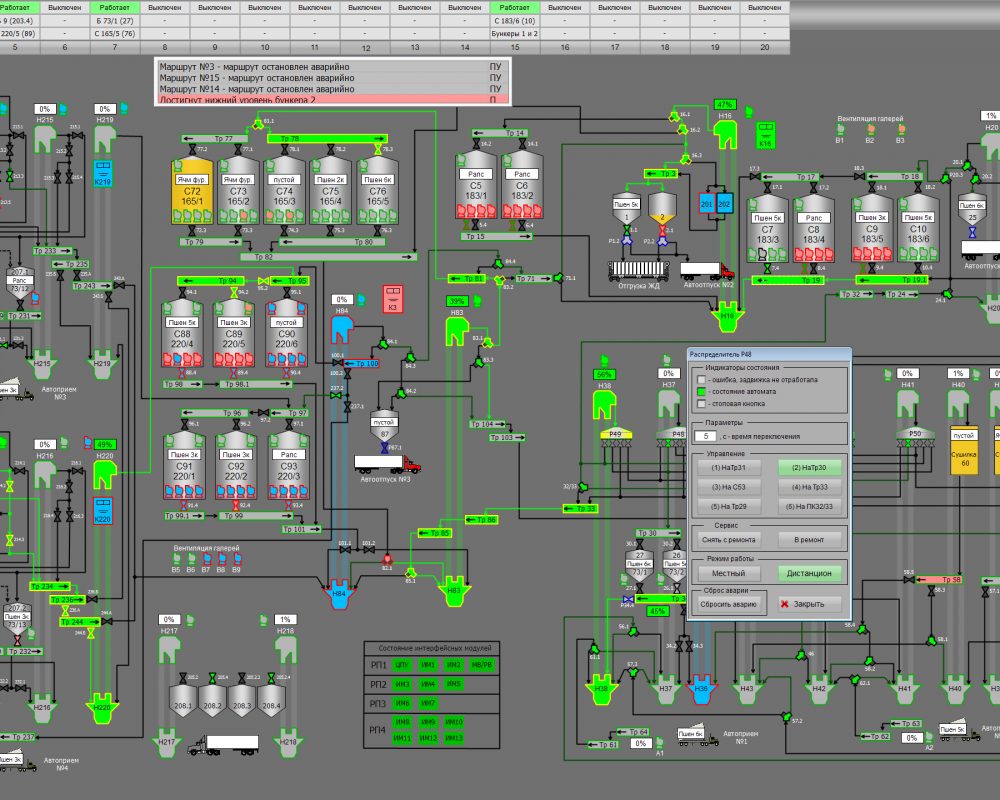

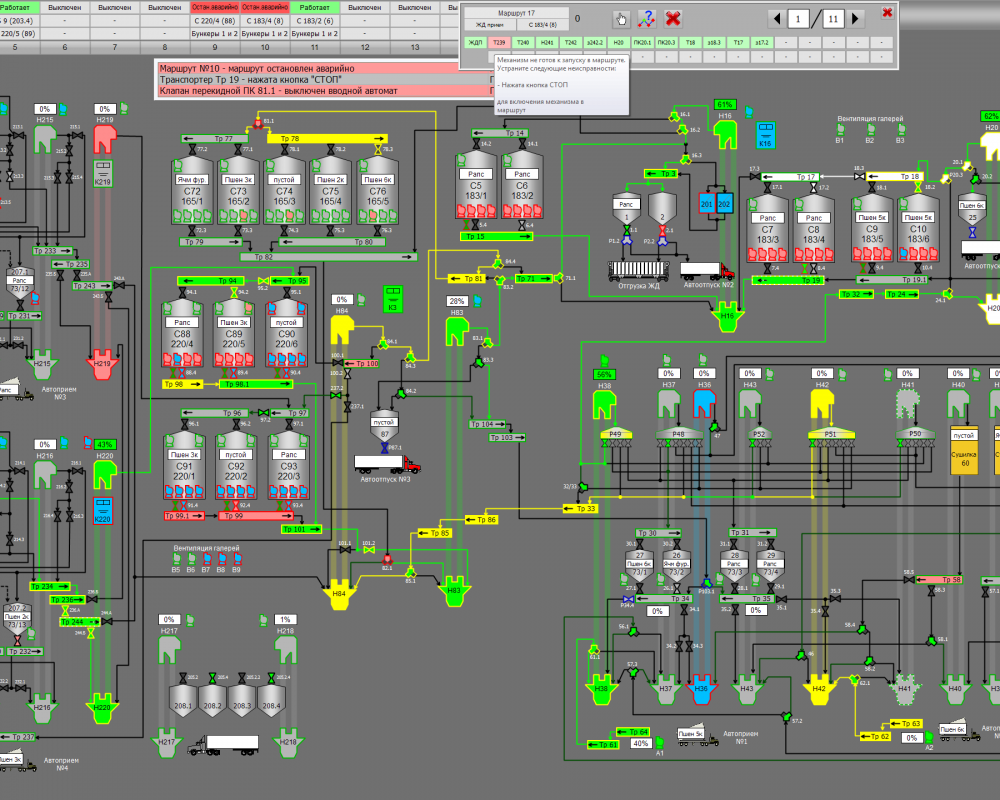

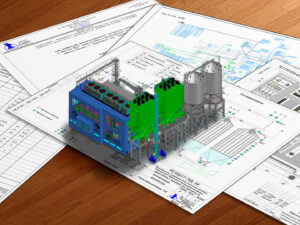

LLC "Servise Grain". Artsiz grain elevator complex. Control and dispatching system

The control and dispatching system operates the equipment of the grain elevator complex:

156 electrical motors

863 measuring transducers (sensors)

143 gate valves and valves

1 operator station

As a result:

Implemented automatic operation of the grain complex with automated construction of technological routes

Features and capabilities

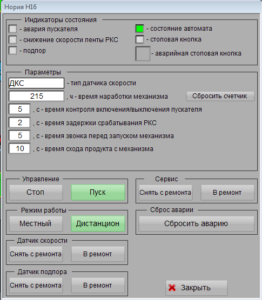

The dispatching system provides:

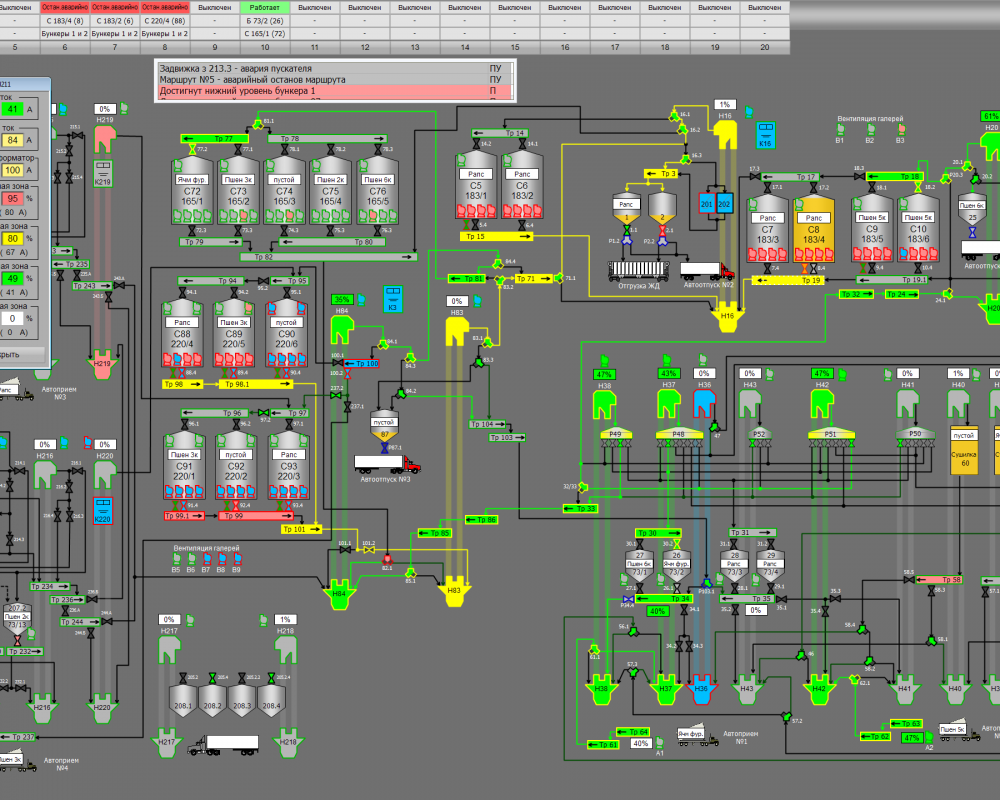

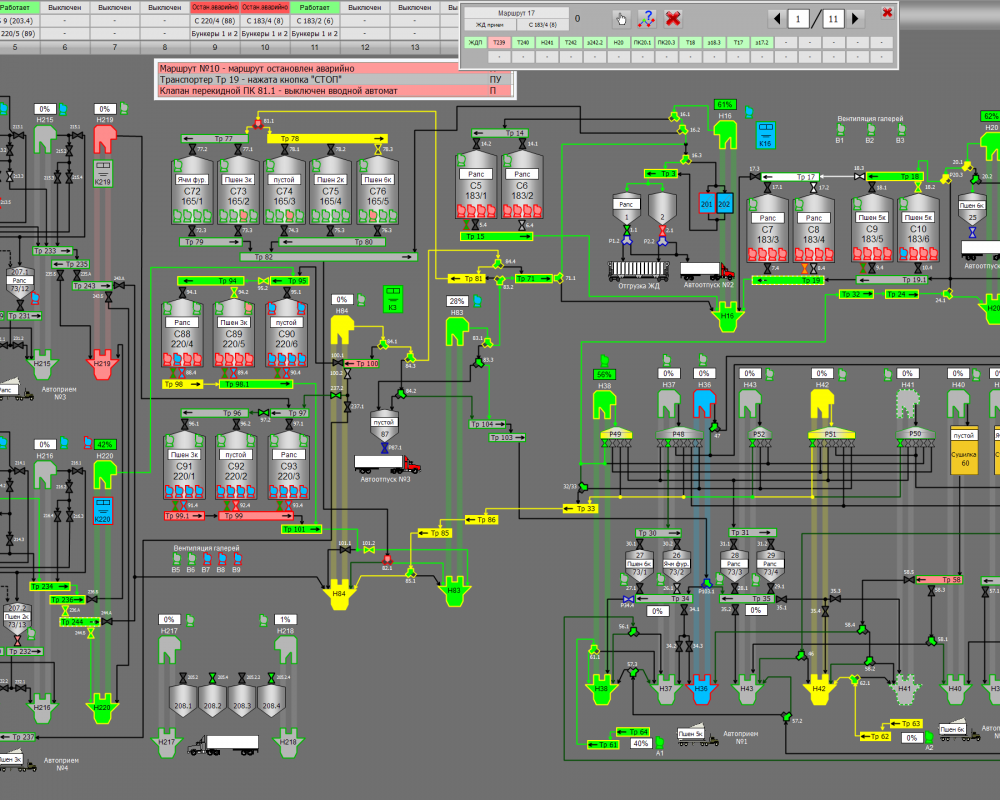

- control of technological parameters and their indication on a personal computer screen (operator’s automated workstation (hereinafter AWS));

- remote or automatic control of actuating mechanism and indication of their state on the AWS screen;

- automatic generation and execution of route start and stop cycles;

The control system (based on PLC VIPA 315) controls the following actuating mechanism:

- norias;

- conveyors;

- gate valves;

- rocker valves;

- flow distributors;

- sirens (pre-start sound signaling).

- emergency signaling devices;

- protective locks.

Control modes

The equipment control system (norias, conveyors, gate valves, rocker valves, flow distributors, separators) provides:

- remote control – automatically, according to the route start/stop the program or by the operator’s command from the workstation screen;

- local control (without using the control system and controller) from the control panel located directly next to the mechanism

Automatic route building

To carry out automatic transportation of grain between two points, using a set of simultaneously operating equipment, the technological elevator routes are used.

The control system is programmed to use 20 routes with 35 elements in each route.

The elements participating in the route are selected automatically from the PC based on the start and endpoints selected by the operator.

Crop indicators are installed on all start and endpoints of the routes, which are designed to inform the operating personnel about the crop at a particular point.

For product receiving points and product shipping points, the crop indicator shows the last chosen crop. The crop indicator is used to block the route construction in case of crop mismatch at the selected endpoints, thereby preventing the accidental mixing of different products.

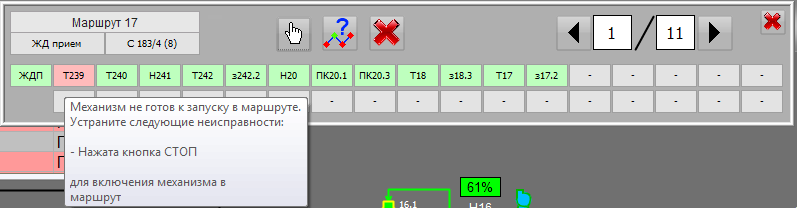

The route status indicator can be in one of the following states: “Off”, “Preparation”, “Prepared”, “Start”, “Running”, “Stop”, “Emergency stop”, etc.

Automatic route building

After selecting the endpoint of the route, the control system will automatically calculate all admissible paths between the specified route points, the calculation results will be presented in the route preparation window.

Each subsequent element starts only after starting the previous one. In case of a failure, further start-up is terminated, and an alarm message is issued to the operator.

The decision to stop the already started route elements or to restart (after eleminating accident’s cause) route elements is taken by the service personnel.

Blocking the switching of the involved devices.

If you try to prepare a route through a diverter valve or a flow distributor that is already occupied in any other route, the system automatically blocks the preparation of such a route, after four minutes this route will be reset and deleted.

When any of the blockings are active, a message is generated on the workstation screen and a sound alarm is activated.

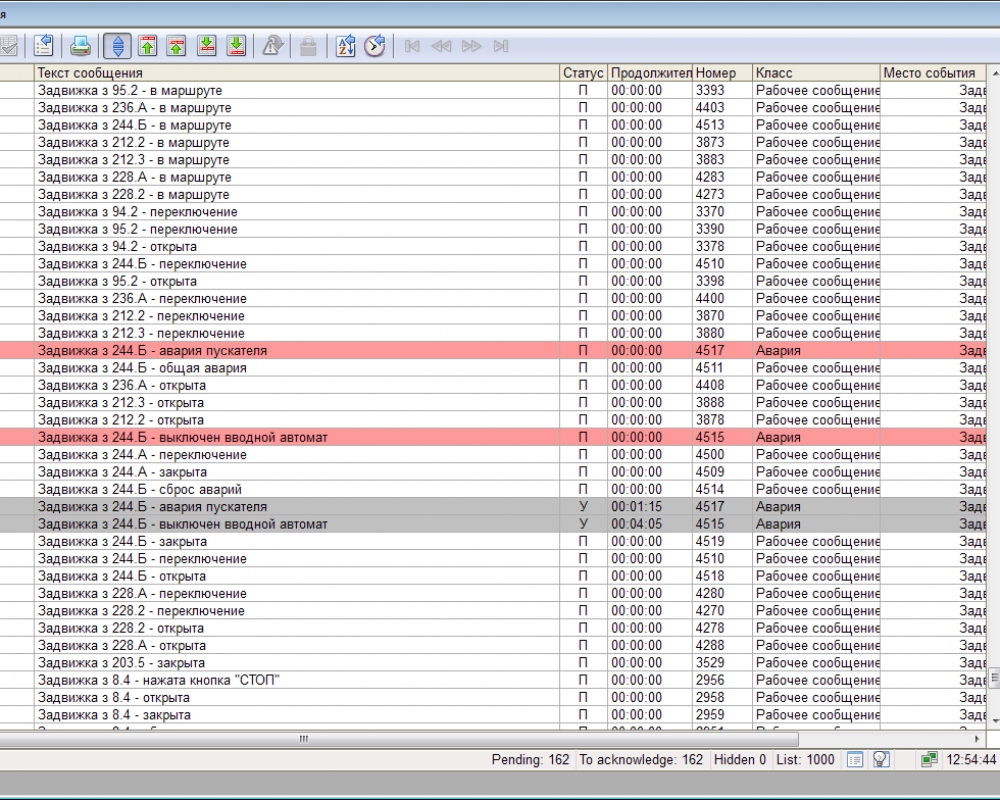

Events archive

The control system provides archiving of all emergency and technological messages, as well as the operator’s actions to turn on / off mechanisms, changing technological settings parameters. Messages are recorded in the archive upon the occurrence and disappearance event’s cause, the operator’s actions.

All messages are recorded in the integrated MS SQL database.

For convenience, it is possible to filter messages by selected conditions. The filtration control window is invoked by clicking the left mouse button on the “Filter settings” button. The message filter is performed by status, class of events, object, element, parameter, as well as the date of their occurrence.