KROPYVNYTSKYI OIL EXTRACTION PLANT, PRIVATE JOINT STOCK COMPANY (KROPYVNYTSKYI OEP,PJSC) Turbine unit with a capacity of 10 MW. Supply of automation panels, installation, commissioning

As a result:

The main and auxiliary systems of the 10MW turbine unit were integrated into the technological process of the enterprise.

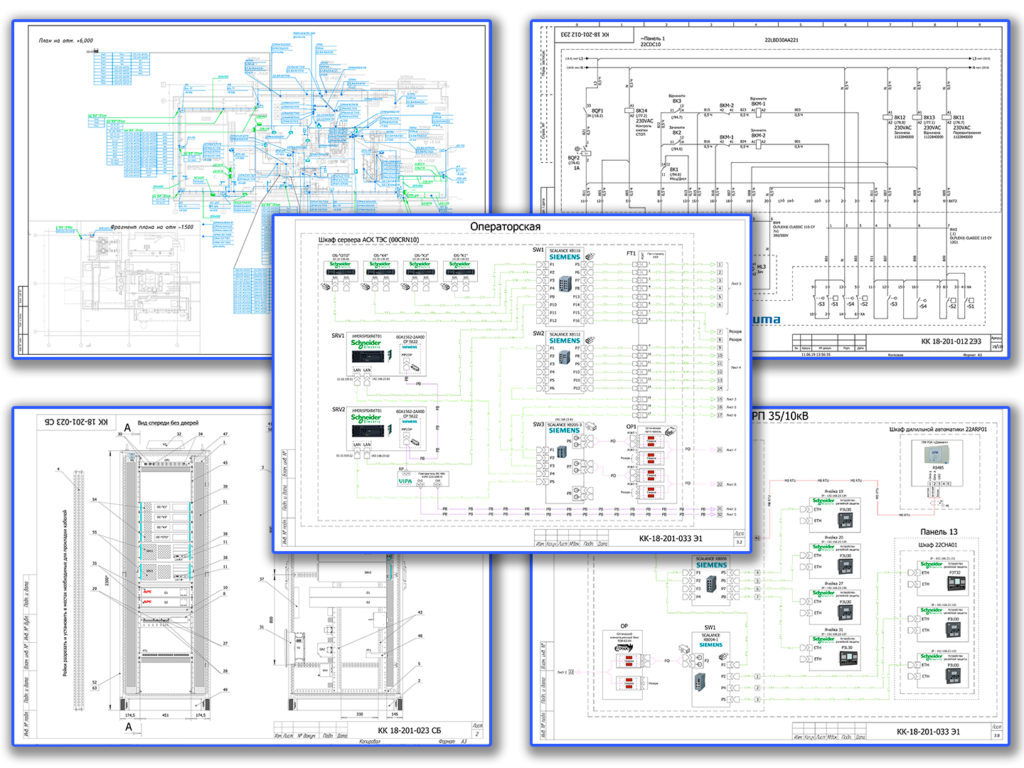

Scope of work:

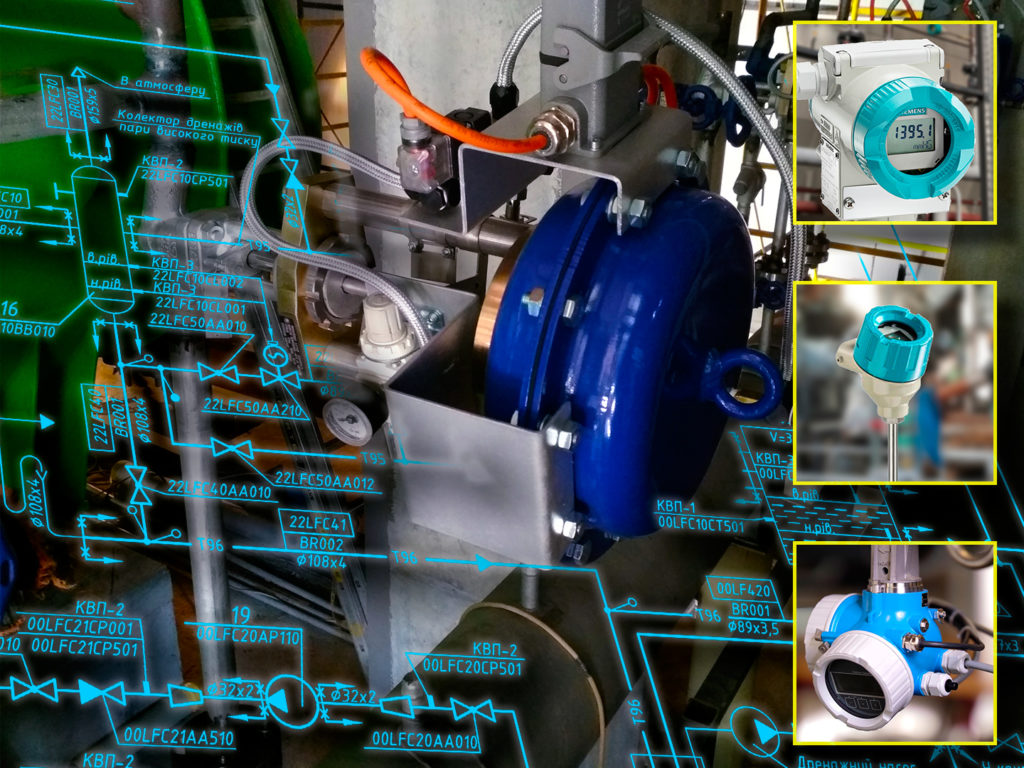

Equipment that has been installed and commissioned during project implementation:

- 23 control panels

- 25 electric motors

- 210 measuring transducers (sensors)

- 45 gate valves and valves

- 41 local control panels

- 47 communication network devices

- 2 redundant central servers

- 4 automated operators and 1 engineering workstation

Completed works:

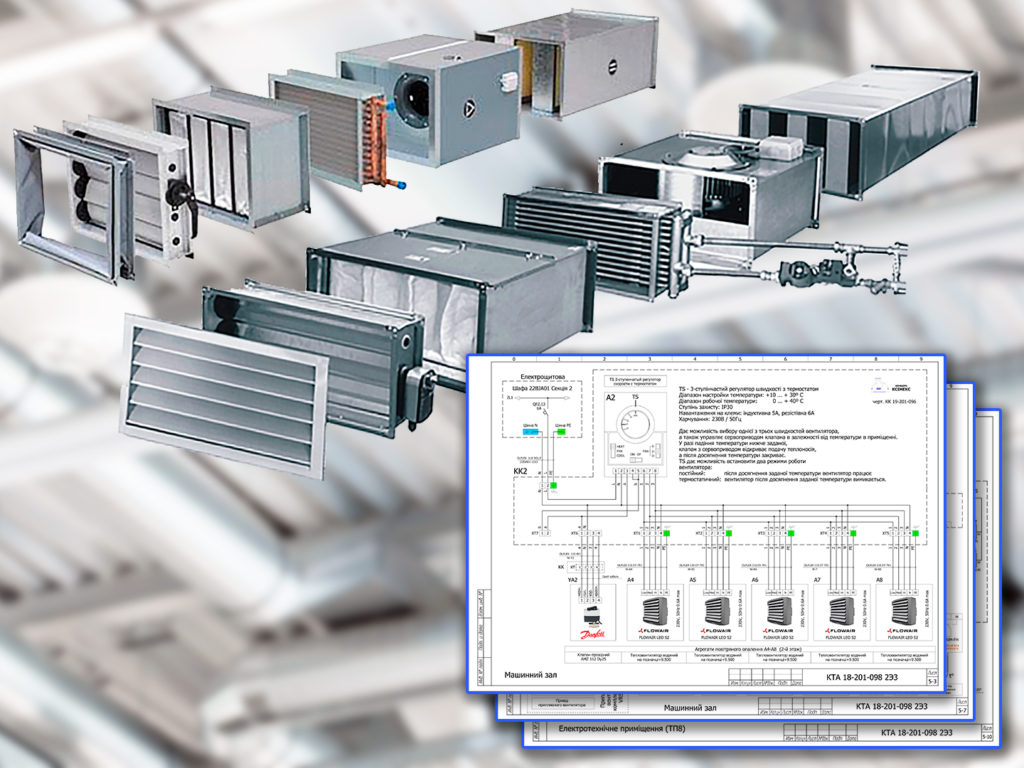

- development, programming, installation, and commissioning of an automatic control system (ACS) for auxiliary equipment of the turbine generator

- electrical installation of the turbine generator ACS made by Siemens s.r.o. according to the manufacturer’s documentation

- design and installation of a communication network for combining all control systems into a single technological complex

- integration of the turbine generator into the general control system

commissioning of all auxiliary control systems

and also:

- design, assembly, installation and commissioning of LV power distribution boards

- installation and commissioning of digital protection terminals for MV power supply and distribution system

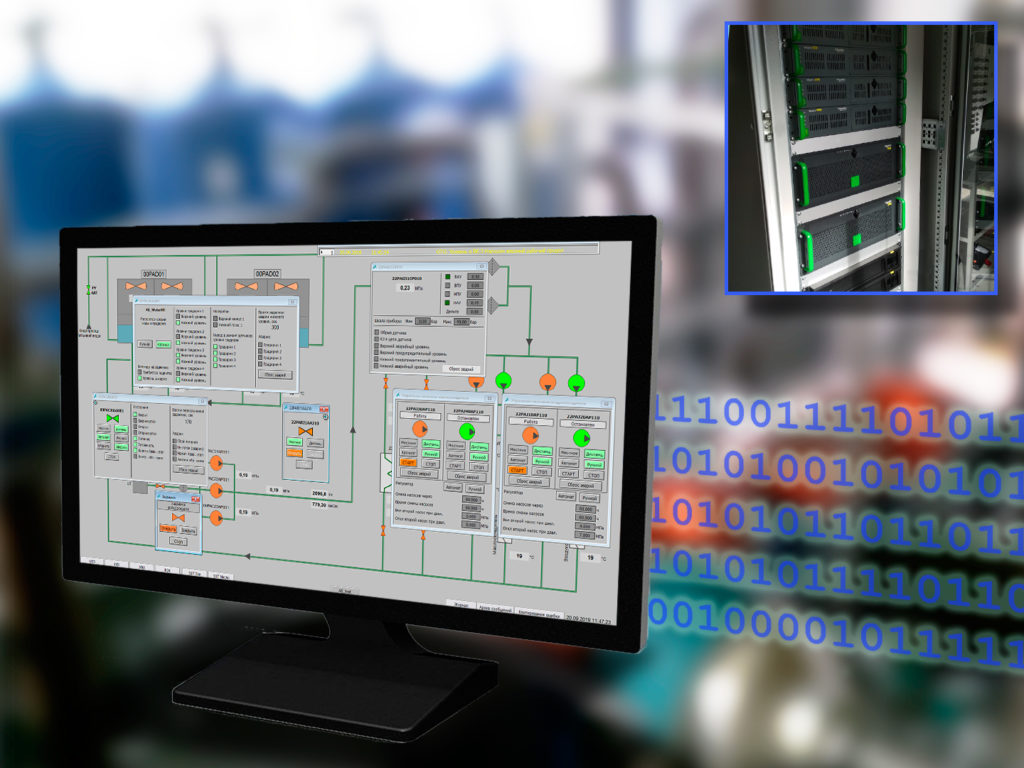

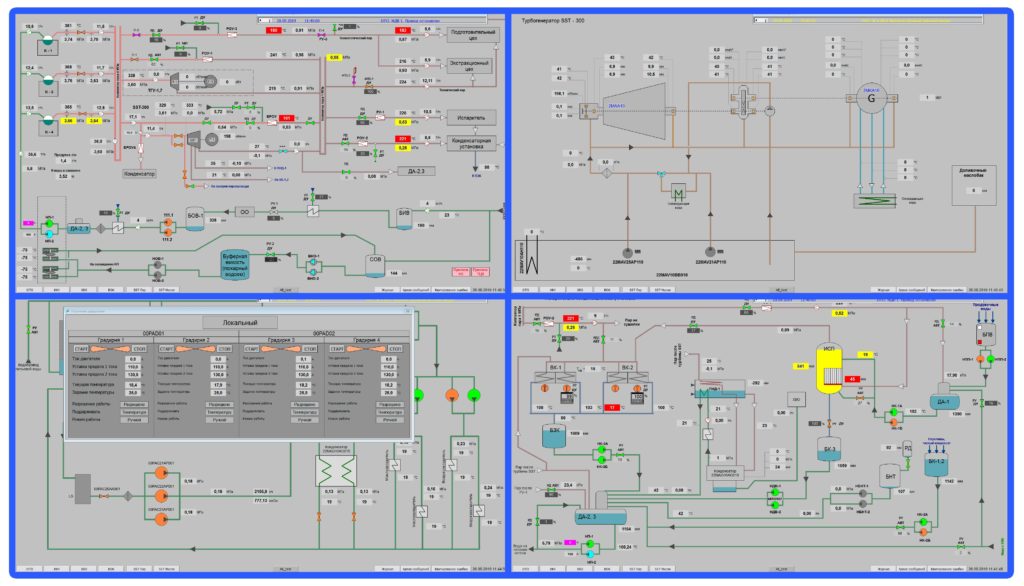

Functions and capabilities of the SCADA-system

The following was performed:

- transfer of the existing boiler house SCADA system to the Siemens WinCC software

- integration of the auxiliary equipment control system of the new turbine unit into the existing SCADA

The new updated SCADA also includes monitoring functions of all main and auxiliary systems of the new turbine generator facility

in particular:

- turbine generator control

- saturated and superheated steam supply

- circulating water pumping station

- cooling towers

- chemical water treatment

- as well as the state of power supply systems

- All events in the facility operation are recorded in the SCADA-system log. Logs are archived

Facility commissioning

To ensure the successful commissioning of the turbine generator facility, our engineering department:

- analyzed the documentation and equipment of all sub-contractors and other involved organizations

- made improvements in power supply and automation systems solutions

- designed a set of documentation for power and control panels

- developed a project solution and designed a set of documentation to combine all control systems into a single technological complex

- conducted full scope of site acceptance tests (SAT) and commissioning procedures acknowledged by control and test protocols