Kropyvnytskyi Oil Extraction Plant, Private Joint Stock Company (Kropyvnytskyi OEP, PJSC)

The project included:

– protection terminal control panels for 35/10kV power transformer and 10kV cable lines;

– 10kV switchgear retrofit;

– turbine generator’s own needs 0.4kV substation.

Relay protection and automation control panels

contains a set of automatic devices designed to quickly identify electrical faults or emergency alarms.

Relay protection operation is based on continuous monitoring of electric power system components and parameters.

- Modern protection devices are built on programmable microcontrollers and meet all up-to-date requirements: speed, selectivity, sensitivity, and reliability.

- The switchboard was designed in accordance with the customer’s specification, which demanded increased reliability.

- The following functions for ACS integration were provided: remote control, reading and changing settings, and reading data from the event recorder and alarm recorder.

Canalis KTA aluminum busbar trunking

Canalis busbars are the part of a comprehensive Schneider Electric offer, which components are designed to work together.

The busbar provides increased safety of people and equipment, continuity of power supply, upgradeability, and ease of use. As a result, optimized electrical installations have high efficiency and complete electrical, mechanical, and communication compatibility.

The offer is perfect for traditional applications (factories, warehouses, shops, etc.) and for the distribution of electrical energy from a transformer to all types of loads in offices, commercial buildings, greenhouses, farms, parking lots, etc.

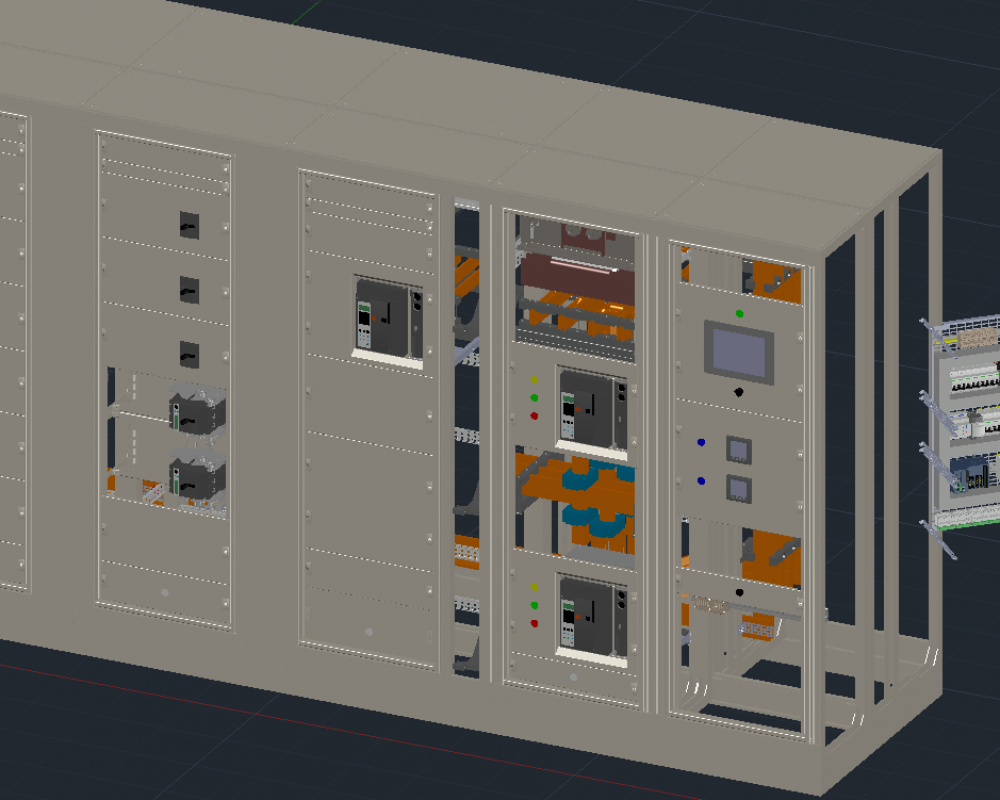

Prisma P - simple, reliable, upgradeable solutions that meet all requirements

Using the Prisma P system, we assemble Schneider Electric “branded” switchboards, traditionally characterized by a high level of safety and optimization:

- All components (switchgear, distribution blocks, prefabricated connection kits, etc.) are fully compatible and ready to work together.

- All possible switchboard configurations, including the most complex ones, have been properly tested.

- At any time, we can prove that our switchboard meets all the requirements of actual standards.

- We create a reliable electrical installation and provide our customers with a total guarantee in terms of uninterrupted operation, the safety of people and property.

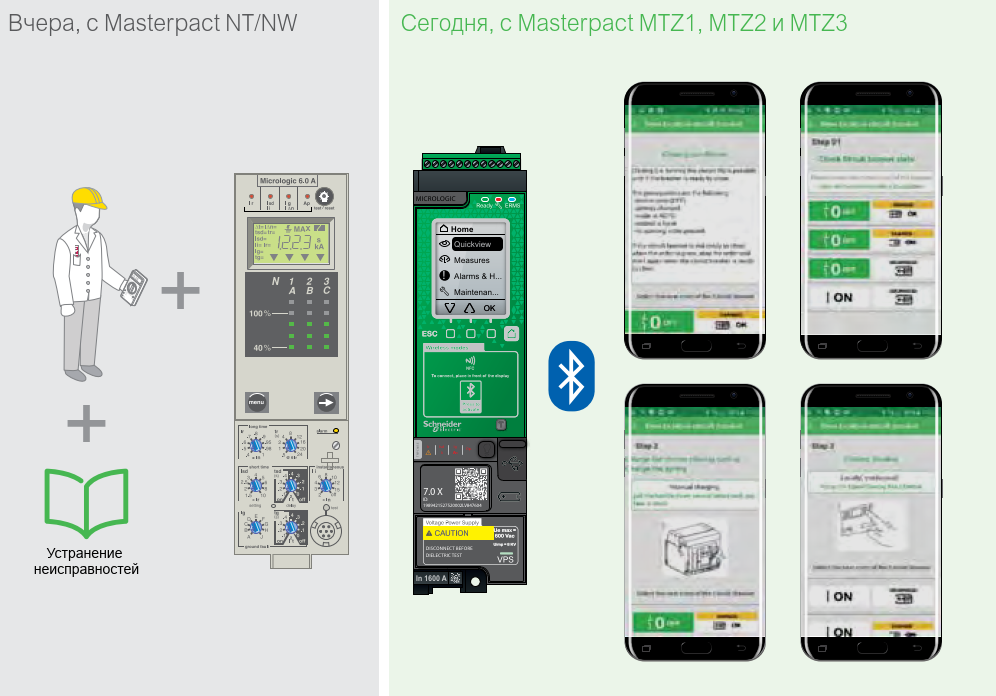

The first switchboard in Ukraine using the innovative Masterpact MTZ circuit breaker

- Micrologic X control units with an intuitive interface provide all types of protection and are highly configurable at any time using digital modules.

- Easy integration into digitally supported switchboards (Smart Panel) and data network connection using a built-in Ethernet connection.

- The interactive interface of Masterpact MTZ smartphone app

Masterpact MTZ: circuit breaker with communication function

The new generation Masterpact MTZ circuit breaker allows monitoring and control using a smartphone.

- wireless secure connection by Bluetooth;

- self-diagnosis, setting of protection functions,

circuit breaker state monitoring and control; - viewing information about consumed energy, power quality

phase balance; - viewing data of the breaker performance.

Withdrawable and withdrawable devices

The use of withdrawable and withdrawable power devices allows you to completely safely upgrade without turning off the power supply of the switchgear, and also increases the safety of personnel during work on the outgoing line or on the switchboard. Withdrawable and withdrawable devices have three positions: connected, test, and disconnected.

Network data collection and transmission to the monitoring system

The switchboard has an industrial controller Modicon M251 with Modbus and Ethernet network interfaces and integrated inputs and outputs.

The Modicon M251 controls the automatic transfer switch and collects information about operating parameters, the state of the devices, and data from the PM5310 measuring devices.

The switchboards have 10-inch Magelis operator’s touch panels, which display a mnemonic diagram showing the status of all devices. The operator’s panels are connected to a common data collection system.

Comprehensive site acceptance tests and commissioning

Upon completion of the electrical installation works, our electrical laboratory specialists performed all the required tests, measurements, and commissioning procedures, among them:

- electric motors insulation resistance measurements

- power and control cables insulation resistance measurements

- protective earth loop resistance measurement

- contact resistance measurement between the ground electrode and electrical equipment

- “phase-zero” loop resistance measurement

- low voltage circuit breaker’s current injection tests

- ATS system functionality checking

- adjusting electrical equipment’s parameters and setpoints