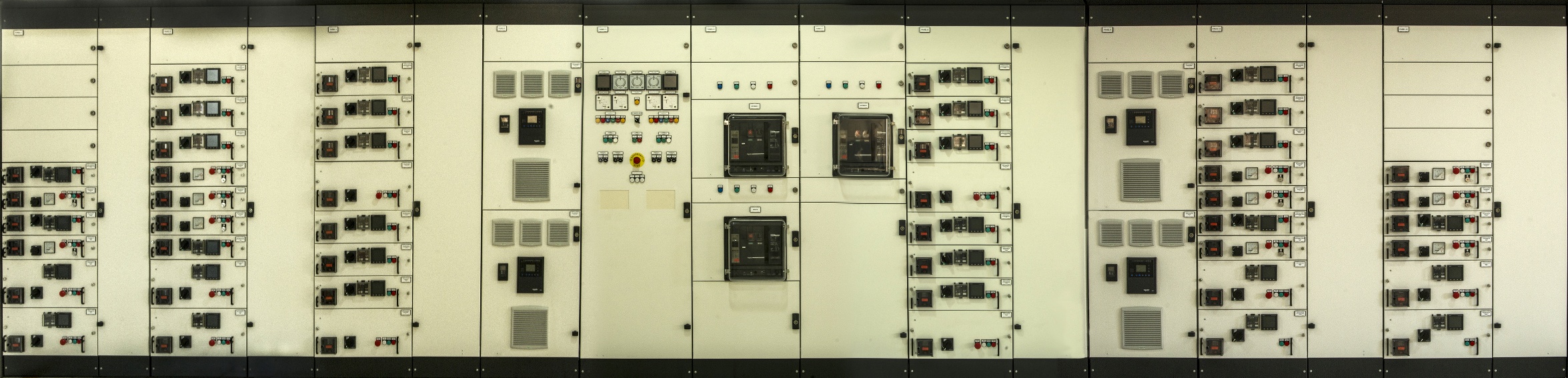

MOTOR CONTROL CENTER (MCC)

MCC SCOPE AND DESCRIPTION

- Service life of electric drive

- Stability of its work

- Regulation accuracy and, as a result, products quality

- Ontime disconnection to prevent failure of electrical equipment and electric drive

- Drive operating parameters diagnostic tools (voltage, current, torque, etc.)

- Ease of control and safe operation

- Safe maintenance, repair, replacement, connection/disconnection of equipment without stopping the technological cycle

CONCERN KSIMEX LLC SOLUTIONS

Our company solves the most complex tasks for customers in any industry using type Okken, Spacial and Prisma enclosures from Schneider Electric (more details “POWER DISTRIBUTION SWITCHBOARDS UP TO 7300A”)

MCC is the part of the overall technological process control system. In addition to MCC we offer PLC automation boards and SCADA systems (Supervisory Control and Data Acquisition system) , so we can successfully implement complex automation and power supply projects for entire industrial enterprises.

- Unsafe switchboard operations. While equipment is comissioned there is a risk of touching live parts of another mechanism's equipment.

- To replace faulty control elements, it is necessary to power off the entire control panel. Thus, it is necessary to turn off all mechanisms powered by this switchboard which will stop whole technological process.

- It's not possible to test mechanism's control circuit, without turning on the electric drive itself.

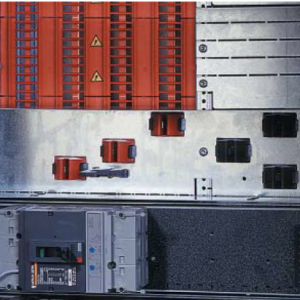

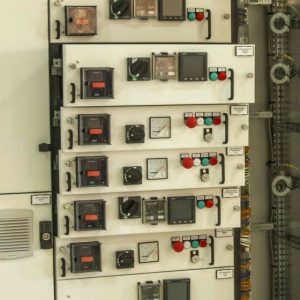

Modern trends of switchboard equipment, like Okken solution from Schneider Electric, make it possible to implement a modular design of a switchboard with draw-out units. This allows to place equipment separately for each mechanism.

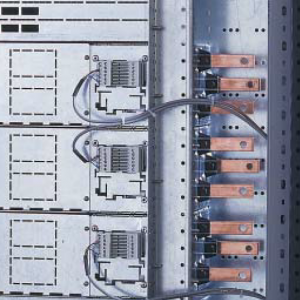

Universal system of supporting structures and busbars allows to create panels with both rear and front connections while ensuring an optimal level of access. Different types of outgoing lines can be combined in one panel or switchboard. It is possible to combine distribution outgoing lines and outgoing motor control lines.

Okken MCC solutions

Unification and modularity

- Draw-out unit with control elements on the front panel allows to create a functional block that can be installed in “Connected / Test / Disconnected / Removed” positions.

- The same power rating and schematic units can be removed and replaced without interrupting the power supply.

Safety

Connection and fixation

Service positions of units

Sliding withdrawable auxiliary blocks

MCC INTELLIGENT SWITCHBOARDS (iMCC)

Programmable logic controllers, multifunctional protection and motor control relays, when included in MCC switchboards, make it possible to build intelligent motor control board iMCC (intelligent Motor Control Center).

A motor control board (MCC) is called an intelligent control board (iMCC) when its main control functions are connected to the PLC so the programmable logic controller is able to independently receive and analyze information about the motor condition and affect on its power components.

iMCC main advantages:

- Improves overall efficiency, reduces on-site installation and setup times

- Reduces commissioning time: the whole process becomes clearer, errors are detected and corrected faster, and problem solving during commissioning is easier

- Improves motor protection: more accurate sensors, more accurate motor models, plainness of changing protection parameters

- Reduces downtime: alarm before tripping, detailed tripping information, statistical information

- Reduces cost of ownership: less downtime, faster troubleshooting, reduced spare parts inventory. Failure statistics helps to organize effective preventive maintenance.

CONCERN KSIMEX LLC provides these solutions based on client’s needs.

By adding multifunctional smart motor protection relays to conventional MCC switchboards (for example Tesys T by Schneider Electric ) instead of common thermal relays, we can get …

Numerous protective functions:

- voltage monitoring

- phase control

- insulation monitoring

- current monitoring

- leakage current monitoring

- thermal protection

- thermistor protection

- automatic reclosing with time delays

And also additional functions:

- Local control terminal

- Currents, voltage, frequency measurements

- Power measurement

- Cosφ measurement

- Leakage current measurement

- Statistical functions

- Alarm log

- Diagnostic functions

- Service data (motor running time, last start time, etc.)

- automation systems integration

- (Modbus, CANopen, Profibus DP, Ethernet TCP/IP)

- groups of drives management

- backup and / or cascading function

- drive's status data collection

- "upper level" systems communication (central PLCs, SCADA systems)

- etc.