"Negotsiant" business center (Odessa) building management system (BMS)

Complex turnkey project:

– building management (BMS)

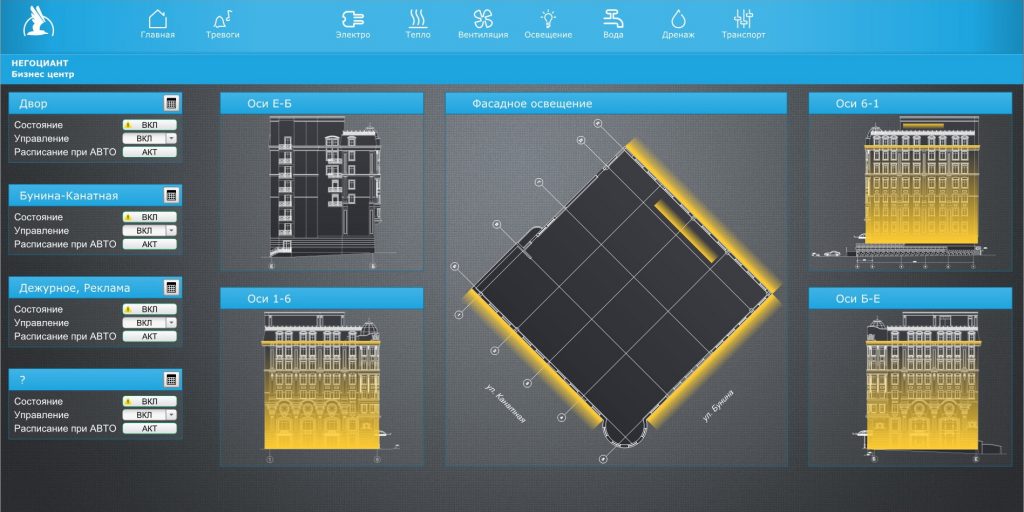

– lighting control

– power supply

General description

- Development of design documentation;

- Supply of automation panels and software; SCADA system design;

- Installation and commissioning works;

- Warranty and service maintenance

- Installed hardware and software:

- Xenta 700 controllers

- Input/output modules (IO)

- Vista Server 5

- Integrated systems:

- power supply and lighting control, ventilation, heat supply (boiler room), water supply, transport system (elevators), offices energy counting.

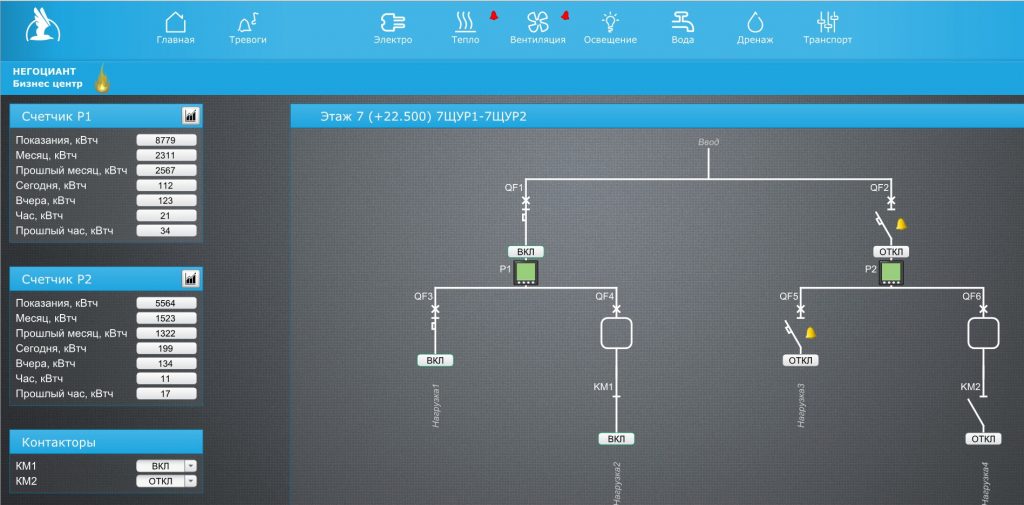

Integration of the power supply system

The integration of the power supply system is carried out using the Modbus RTU protocol (multifunctional meters, ATS) and discrete signals. The transmission of the following signals is provided:

Main distribution board:

- incoming circuit breaker faults;

- voltage presence control;

- power supply quality;

- circuit breakers state control;

Office power supply boards:

- incomer circuit breaker state;

- backup power circuit breaker state;

- input contactors state;

- power supply management separately for each office;

- automatic changeover system for emergency power supply.

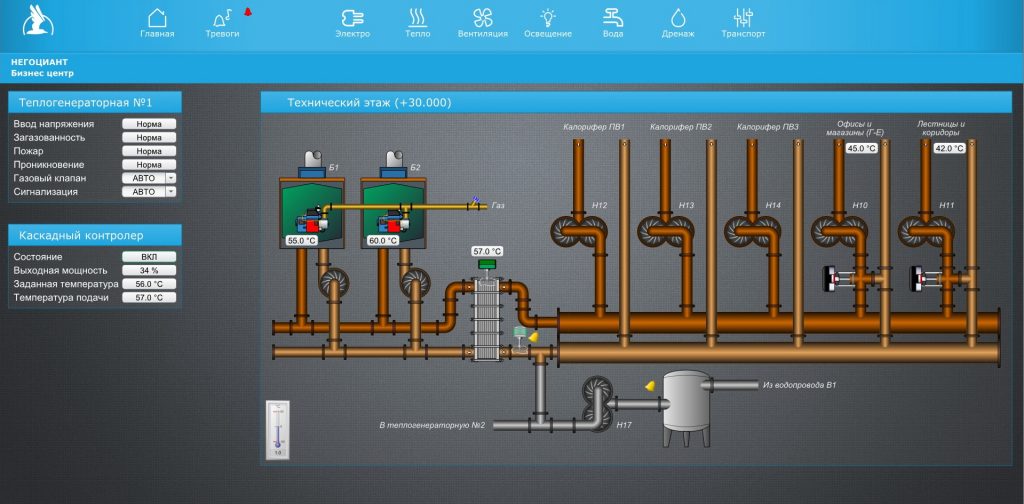

Boiler equipment

Boiler room equipment integration using LonWorks protocol. The transmission of the following main signals is provided:

- power supply failure;

- system water pressure;

- fire in the boiler room;

- gas pollution in the boiler room;

- gas pressure below normal;

- gas pressure above normal;

- circulating pumps failure;

- feeding pumps failure;

- state of the control valves;

- state of the safety gas valve;

- state of boilers;

- heat transfer agent temperature;

- outside air temperature;

- boiler room temperature.

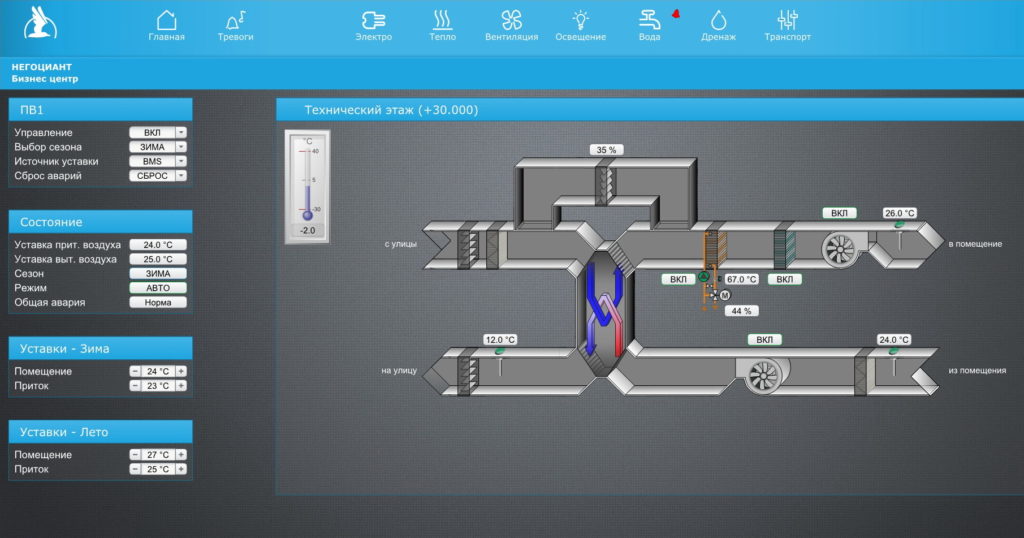

Ventilation system

Ventilation units integration using Modbus RTU protocol. The transmission of the following main signals is provided:

- equipment operating mode selection;

- temperature setting;

- air heater freezing alarm;

- air dampers state;

- filter logging alarm;

- fan motors state;

- pump motor state;

- 3-way valve actuator state;

- outside air temperature;

- supply air temperature.